Through regular monitoring of lubrication, noise, frequency spectrum, thermography and endoscopy, we detect damage of gearing at an early stage. In addition, we use special professional methods (magnetic particle inspection) to detect hidden defects so that we can repair or replace parts efficiantly.

Over 80% of gearbox failures are directly related to the lubricants. The general condition of a gearbox can be determined on the basis of the actual condition of the lubricant used. We offer modern and innovative oil monitoring systems as well as proven control procedures. After a professional oil analysis by our experts we can asses the condition of your gearbox more accurately

Our experts use infrared cameras to observe the heating process and localize areas of high heat stress. This diagnostic method is also used during commisioning after a repair to identify possible weak points.

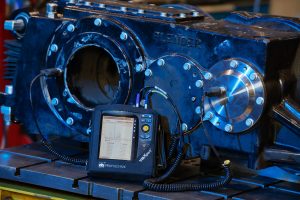

Any gear damage can be detected and rectified at an early stage due to a precise frequency spectrum analysis. Using a portable vibration analyzer, we operate independently of location and carry out the measurements directly on site at the industrial plants.

By inspecting all accessible rolling bearings and gears we can detect fatigue wear, micropitting, microcracks or even more serious wear immediately.

To ensure that you can keep an eye on the condition of your systems at all times and detect wear, water content, particles etc. in good time, it is advisable to implement an early warning system as part of an overhaul. The sensor system shows you whether a repair is necessary and also helps you to prepare for an oil change timely.

Through regular monitoring of lubrication, noise, frequency spectrum, thermography and endoscopy, we detect damage of gearing at an early stage.

Repairs save you money and time.

Regardless of the manufacturer and date of manufacture of the gearbox we have the right spare parts for you.

Proper maintenance of machinery and equipment prolongs its lifetime. Qualified and well-trained employees play a key role in this.

Through regular monitoring of lubrication, noise, frequency spectrum, thermography and endoscopy, we detect damage of gearing at an early stage.

Repairs save you money and time.

Regardless of the manufacturer and date of manufacture of the gearbox we have the right spare parts for you.

Proper maintenance of machinery and equipment prolongs its lifetime. Qualified and well-trained employees play a key role in this.

Kaspar-Zeitlinger-Straße 32

4563 Micheldorf in Oberösterreich

Österreich

Tel.: +43 699 106 818 90

E-Mail: office@lubex.at